LIFESTYLE

Heavy Metal in Lightweight Aluminium

Aluminium instruments are catching on, including Alusonic's bass guitars out of Italy.

10 October, 2016

Once it became available, 3D printed aluminium was bound to be used for innovative instruments.

Based in the Netherlands, Xilloc has already made a name for itself with 3D printed medical implants to help patients after a bicycle accident or a cancer diagnosis – so printing an aluminium electric guitar was a bit of a departure. Nonetheless, the company took the plunge. In partnership with Swedish designer Olaf Diegel, Xilloc is making headlines with a "Heavy Metal" instrument made out of some of the lightest metal available.

This latest of Diegel's creations is a custom six-string guitar, with artistic detail in the aluminium body that features barbed wire and roses. The design has nothing to do with Axl Rose of Guns N' Roses, nor with the popular American country song "Barbed Wire and Roses," although that tune would probably sound good on this Telecaster-shaped instrument. The name came from Diegel originally envisioning the project under the name "War and Peace."

This latest of Diegel's creations is a custom six-string guitar, with artistic detail in the aluminium body that features barbed wire and roses. The design has nothing to do with Axl Rose of Guns N' Roses, nor with the popular American country song "Barbed Wire and Roses," although that tune would probably sound good on this Telecaster-shaped instrument. The name came from Diegel originally envisioning the project under the name "War and Peace."

Diegel, an engineering professor at Lund University, specializes in additive manufacturing techniques and the role of 3D technology in rapid product development. He has spent two decades in the field and helped bring to market everything from theater lighting to home health monitoring products, but in 2012 he started creating 3D guitars and bass guitars. That led to Diegel launching his ODD Guitars business.

The selective-layer sintering technique used in other ODD guitars used Duraform PA to build the components. The Spider, designed specifically for laser sintering and weighing in at less than 3 kilograms, features little spiders covering a 3D printed body with a mahogany core. There's a larger version of the Spider available as well, in addition to seven other body designs in Diegel's studio.

The selective-layer sintering technique used in other ODD guitars used Duraform PA to build the components. The Spider, designed specifically for laser sintering and weighing in at less than 3 kilograms, features little spiders covering a 3D printed body with a mahogany core. There's a larger version of the Spider available as well, in addition to seven other body designs in Diegel's studio.

Images: ODD Guitar

Among them is the Steampunk, which captures the industrial theme with 3D-printed gears and diamond-shaped grating carefully airbrushed by New Zealand artist Ron Van Dam. The gears and piston incorporated into the design move when a player powers up the guitar. Alongside the Steampunk guitar, Diegel created an entire band that includes keyboards and a five-piece drum set. Like the Steampunk, the other instruments are made of Duraform PA.

Nylon-plastic like Duraform PA is commonly used in additive manufacturing, but with Heavy Metal, the Swedish professor wanted to move into aluminium. Diegel says he hoped to better understand the "intricacies of the whole process, from 'design for additive manufacturing', to the actual 3D printing of the guitar, to the post-processing that is required to go from a 3D-printed metal part straight of the machine to a usable masterpiece."

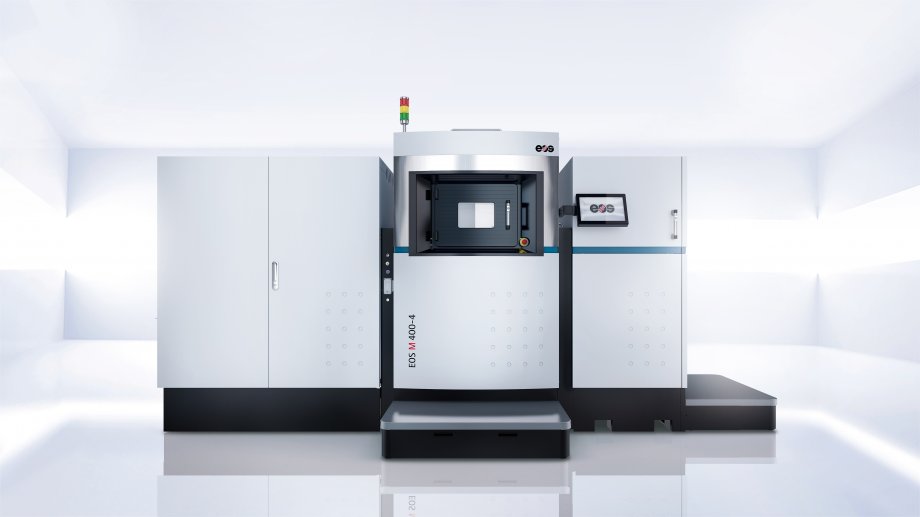

Image: EOS

Despite the intricacy of its design, the body was printed as a single piece, using an EOS M400 metal additive manufacturing system made available by Xilloc. The result, when finished, is a guitar that weights just 3.7 kilograms.

The aluminium guitar is then shot peened (a finishing process that creates a compressive residual stress layer on metals by blasting them with small, spherical shot) to achieve its finish, a process Diegel presents in before-and-after images. Those photos are in a collection he created for the guitar's entire manufacturing journey, from its origins in a Solidworks CAD software program to the final body. Diegel then adds a Warmoth Pro Telecaster maple neck and 22-fret board, with a Schaller 475 flat-mounted bridge for six strings and other high-quality components. Of course, all of these are customizable if customers prefer other options.

The hardest part, Diegel said, is removing all of the support material by hand after the laser-sintering job. There is no word on whether it can be smashed on stage or in a hotel room, but given aluminium's durability, breaking the Heavy Metal apart will likely be a tall order.

The aluminium guitar is then shot peened (a finishing process that creates a compressive residual stress layer on metals by blasting them with small, spherical shot) to achieve its finish, a process Diegel presents in before-and-after images. Those photos are in a collection he created for the guitar's entire manufacturing journey, from its origins in a Solidworks CAD software program to the final body. Diegel then adds a Warmoth Pro Telecaster maple neck and 22-fret board, with a Schaller 475 flat-mounted bridge for six strings and other high-quality components. Of course, all of these are customizable if customers prefer other options.

The hardest part, Diegel said, is removing all of the support material by hand after the laser-sintering job. There is no word on whether it can be smashed on stage or in a hotel room, but given aluminium's durability, breaking the Heavy Metal apart will likely be a tall order.

Banner image: ODD Guitars